By acting within this letter range, the operator is ensuring a safe lift or placement for the materials. These are denoted on the telehandler load chart by letters ranging from A-H, and sometimes beyond. Once these factors have been determined, the operator must maneuver the unit to the correct placement/retrieval position.

If the boom extends to 25ft, this reduces the capacity to 2,000 lbs. When hauling materials within 5-10ft of the unit, it has a lift capacity of 8,000 lbs. Let’s use the GTH-844 chart as an example. Reach is shown on the bottom, lift on the left side, and capacity in the middle of the chart.Īs a general rule of thumb, telehandlers lose lift capacity as the boom moves further away from the unit.

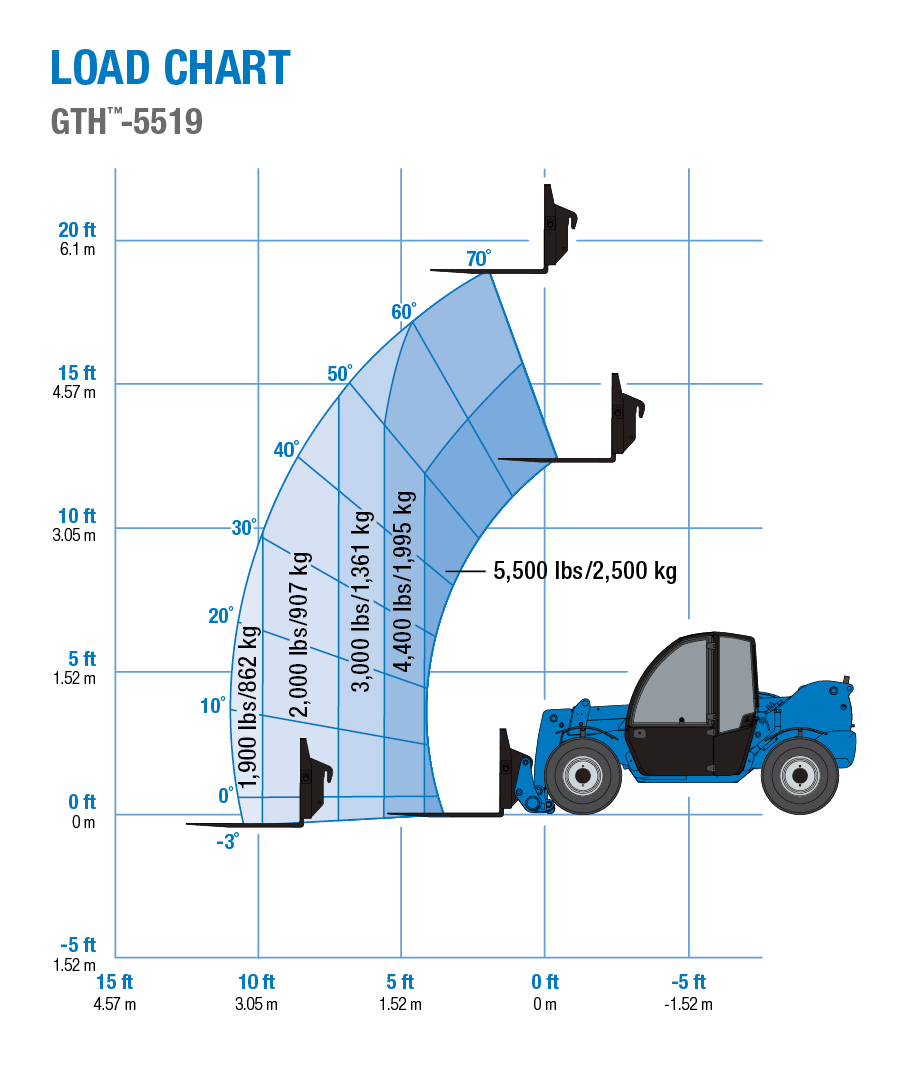

This range reflects the retracted and extended boom positions. Each telehandler load chart contains a grid that shows the maximum reach and lift range of the unit. Reading load charts can be difficult at first, but operators must understand them to stay safe. A telehandler load chart often looks like these JLG and Genie charts: This chart acts as a quick reference guide for operators when they are transporting materials. That’s why every unit features a telehandler load chart in the cab. Operators must assess these conditions and understand the capabilities of their telehandler before transporting materials.

Certain materials may also require a special attachment for effective handling. These include weather conditions, the size and weight of the materials, and the height it needs to be lifted to. When hauling materials, many factors can change how a load should be handled. Transporting, placing, and retrieving loads is a daily activity for many applications. Telehandler load charts are a crucial yet sometimes overlooked part of safe operation.

0 kommentar(er)

0 kommentar(er)